Galerie

The dual-fuel feature allows this oven to offer different heating combinations to suit all types of baking. Depending on your requirements, you can also choose to heat only part of the oven.

Even heat distribution, with no temperature drop, is assured by 20-mm thick refractory cement slabs and 14-mm diameter heaters. Baking is by conduction and radiation, as in a brick oven.

Description

- Type 304 austenitic stainless steel front (hood, control panel, work surface).

- Hood with in-built steam extractor.

- Option of 1 or 2 electric levels.

- 2 to 4 annular tube levels (gas or oil).

- Electronic temperature controller.

- Top and bottom temperature controller.

Advantages

- Fast heat-up.

- Excellent insulation.

- Very low energy consumption.

- High-performance steam generation.

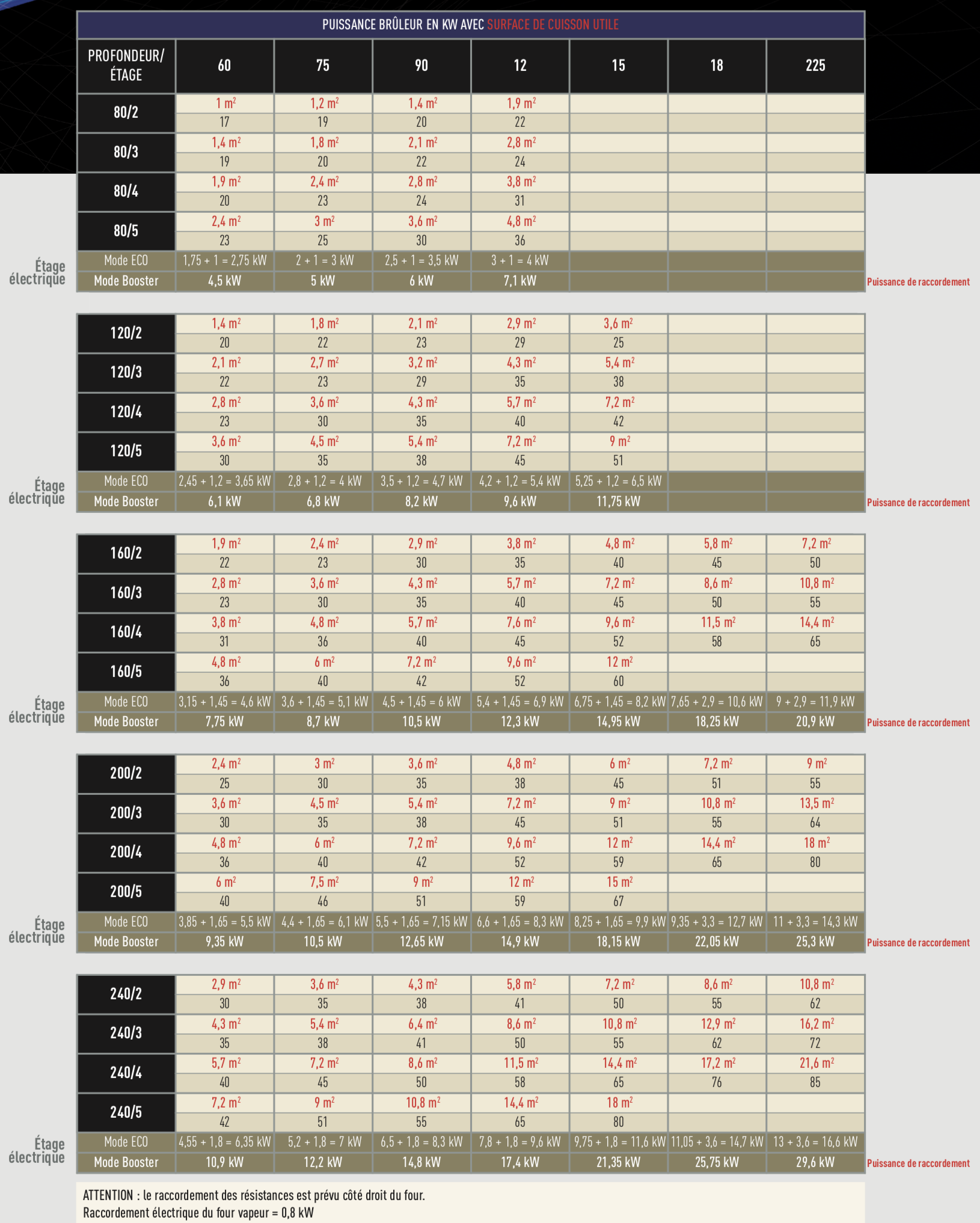

Electric levels: option of 1 or 2 electric levels.

With sophisticated insulation between the top annular tube level and the electric level, the Optima dual-fuel oven takes full advantage of thermal radiation coming from the lower levels while still allowing a temperature differential of 40 °C to be maintained.

These levels can be used in “eco mode” or “boost mode” to provide 80% additional heating power.

The oven's excellent insulation and use of heat from the lower levels deliver very low energy consumption.

Warranties*

Electric heaters: 5 years

Gas or oil annular tube levels: option of 2, 3 or 4 levels

Fast heat-up: 2 °C per minute thanks to the stainless steel hearth’s high-temperature (1200 °C) refractory exchange surface.

Energy consumption is very low, due to:

- Excellent insulation.

- Highly efficient baking surface.

- Large number of tubes over the depth of the baking chamber (25 tubes per baking metre).

- Very low chimney outlet gas temperatures.

- Very low burner power levels (e.g. 45 kW for a 7m² oven).

High-performance steam generation

Warranties*

Annular tubes: 10 years

Stainless steel refractory hearth: 5 years

*subject to proper use and annual servicing of the burner by a certified professional.

Standard equipment

- Type 304 austenitic stainless steel front, hood and work surface.

- Hood with in-built steam extractor.

- Stainless steel door handles with polished aluminium ball.

- Upward-opening doors in tempered glass, heat resistant to a temperature of 350 °C.

- Dual halogen lighting on each level.

- Loading device and hanging rails.

Fully stainless steel swivelling control panel comprising:

For the electric level(s): electronic top and bottom temperature controller.

For the burner-heated levels: electronic temperature controller.

- Automatic start-up clock.

- Steam timing.

- Automatic On/Off switch.

- Manual On/Off switch.

- Burner switch.

- Lighting switch.

- Steam extractor switch.

- Steam injection push-buttons (note: the steam injection push-buttons are also located on the door handle side of the fascia strip).

- Manual exhaust on each level.

- Electronic control board with electric exhausts.

- Integrated lifter on the front panel of the oven.

- Rear opening.

- Electric level with front and rear opening.

- Stainless steel door cladding.

- Stainless steel door cladding.

- Brickwork façade.

- Brickwork on 1 or 2 sides.